Constant Storage Machinery joins hands with OREE Laser to start a new journey in overseas markets

Release time:

2025-01-16

Foreword

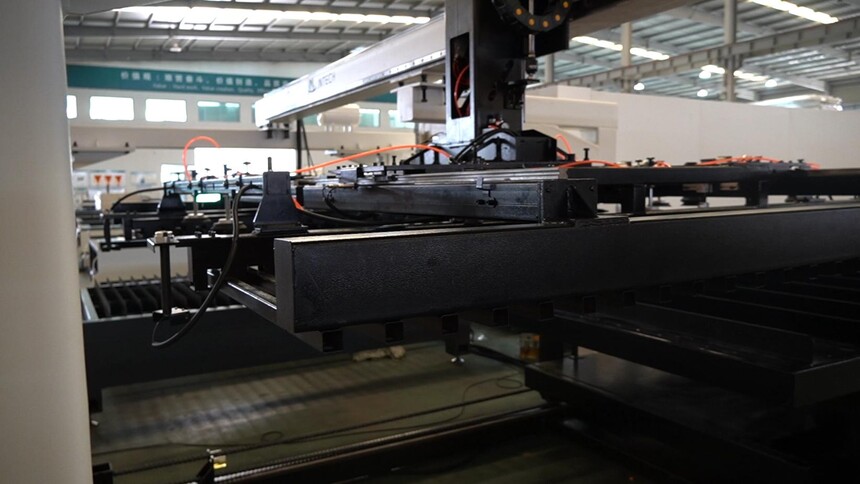

In the process of the global manufacturing industry accelerating towards intelligence and automation, Constant Storage Machinery, relying on strong technical accumulation and powerful R & D capabilities, closely cooperates with OREE Laser to meticulously create a set of efficient and accurate comprehensive automated sheet metal processing production line solutions for overseas customers, fully demonstrating the unique charm and strong strength of China's intelligent manufacturing in the international market.

01

Constant Storage

Strong combination of technological strength

01. Deep optimization of sheet metal processing

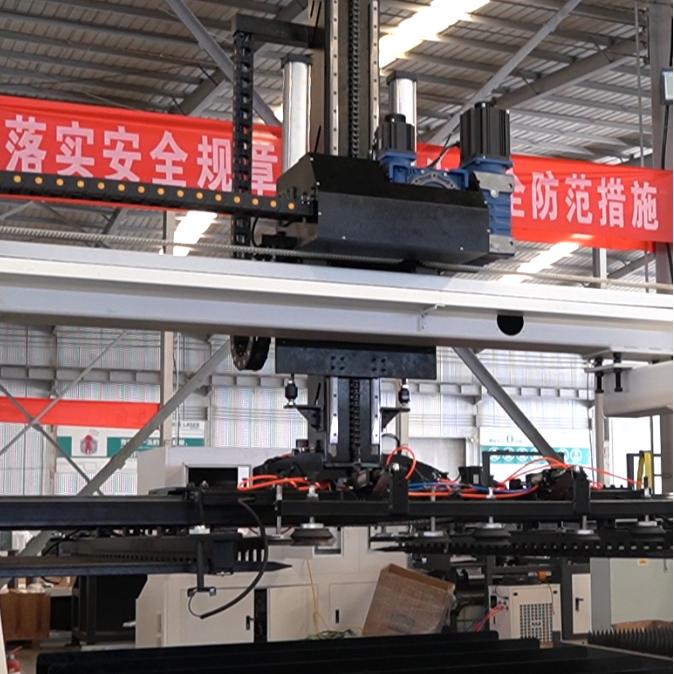

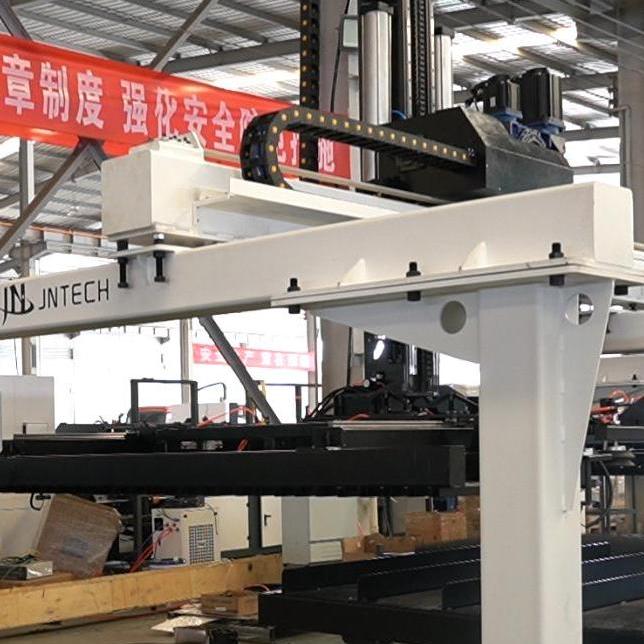

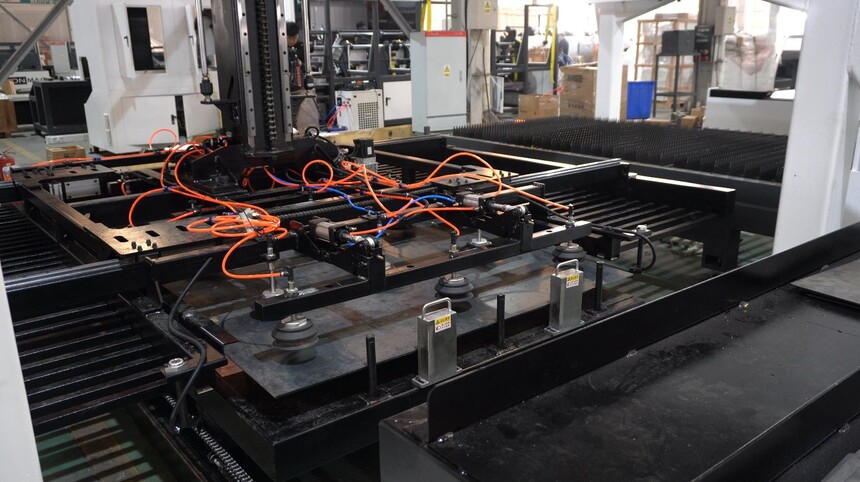

Constant Storage Machinery understands the strict standards of overseas customers for manufacturing processes and spares no effort in the optimization of sheet metal processing technology. For sheet metal materials of different materials and thicknesses, a large number of empirical research and simulation analysis have been carried out, and then the motion parameters and force control of the gantry truss manipulator have been finely adjusted. For thin sheet metal, a more gentle and accurate clamping and handling mechanism has been developed to effectively avoid material deformation; for thick plates, the power output of the manipulator is strengthened to ensure the stability and reliability of the transmission process, so as to ensure that in the entire processing process, regardless of the difference in material characteristics, the ultra-high processing accuracy can be maintained, so that the dimensional accuracy and surface quality of the final product reach the international top level, in line with the strict demands of aerospace, high-end electronic equipment manufacturing and other industries for the precision manufacturing of sheet metal parts.

02. Product function innovation and expansion

Constant Storage Machinery always adheres to the concept of innovation driving, and deeply optimizes the design details of the truss structure of the truss manipulator while maintaining the original high stability and rigidity. Innovatively uses new high-strength alloy materials to reconstruct the connection parts, which significantly improves the fatigue resistance of the structure while reducing the overall weight, ensuring that it can still accurately maintain the motion trajectory under long-term high-speed and high-intensity working environments. With the help of high-precision sensors, key parameters such as material, thickness, and surface flatness are quickly and accurately identified before the material is fed, ensuring that the materials entering the processing process are in a qualified state, and effectively avoids processing defects and equipment failures caused by material defects, which greatly improves the stability of production efficiency and product quality.

02

Constant Storage

A factory that strives for excellence

01. Intelligent control optimization and upgrade

At the level of control system optimization, the PLC control system of Constant Storage Machinery, as the core "intelligent center" of the production line, integrates self-developed intelligent control software. Operators can not only conveniently set processing parameters, start or stop the production line with the help of a simple and intuitive human-machine interaction interface, but also obtain process optimization suggestions generated by the system based on data analysis, further reducing the complexity of operation and significantly improving the intelligent level, controllability and reliability of production experience.

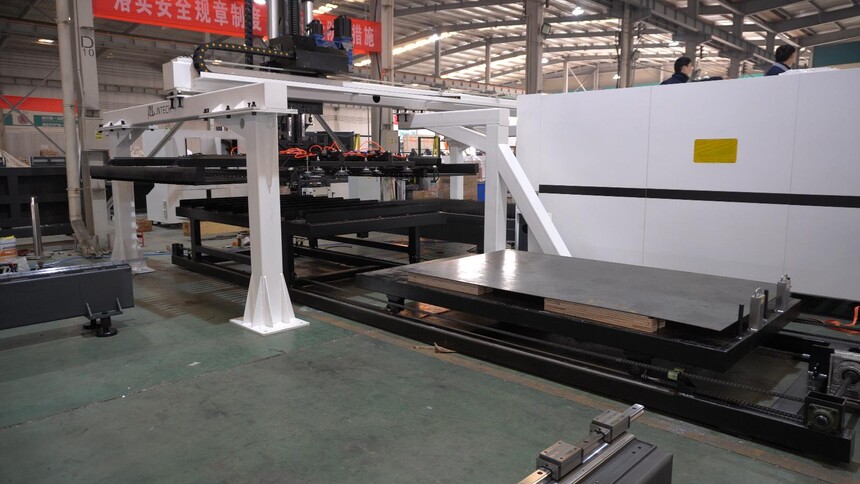

02.Production line synergy mechanism

In the entire automated sheet metal processing production line system, the advanced cutting technology of OREE Laser complements and synergizes with the optimized and upgraded manipulator system of Constant Storage Machinery. OREE Laser relies on its professional research and development results in the field of lasers to output high-power and high-stability laser beams, which fully meet the strict requirements of high-end manufacturing for the processing quality of sheet metal parts. The manipulator of Constant Storage Machinery is like a highly skilled assistant, which methodically and precisely conveys the materials to be processed to the cutting area, and quickly transports the finished products to the double-layer finished material truck after processing. The exquisite design of the double-layer finished material truck realizes the classified storage and efficient turnover of the finished products, further optimizing the overall efficiency of the production process.

03

Constant Storage

Precise control of whole-process management.

01. Perfect quality inspection system

In terms of product quality inspection, Constant Storage Machinery has built a rigorous and advanced inspection system. First, in the process of raw material entry, the chemical composition and internal defects of sheet metal raw materials are comprehensively tested to ensure that the quality of raw materials meets high standards. During the processing process, multi-dimensional online inspections are set up at key process nodes to check the surface roughness and hole quality of the processed surface in real time, effectively preventing the generation and circulation of defective products. After the processing is completed, the product enters a dedicated finished product inspection area, which is equipped with precision testing equipment. According to international Quality Standards and customer customization requirements, the dimensional accuracy, shape and position tolerances, microstructure and mechanical properties of the finished product are comprehensively tested. Only fully qualified products will be allowed to enter the packaging and delivery process, thus ensuring that every product delivered to overseas customers has excellent quality.

02. Solid guarantee for overseas after-sales service

In the process of overseas market expansion, Constant Storage Machinery has carefully constructed a complete after-sales service network system to provide customers with all-round and all-weather technical support and solid guarantee. The professional after-sales teams distributed all over the world are composed of experienced and highly skilled engineers. They are familiar with local languages and cultures and can quickly respond to customers' after-sales demands. Whether it is equipment installation and commissioning, daily maintenance, or emergency repair of sudden failures, the after-sales teams can arrive at the scene in the shortest time. With professional technical tools and rich practical experience, they can quickly diagnose the root cause of problems and provide practical and effective solutions to ensure the stable and efficient operation of the production line and minimize the adverse impact of downtime on customer production, so that overseas customers have no worries.

Postscript

The in-depth cooperation between Constant Storage Machinery and OREE Laser is not just a simple integration of technology and products, but also an all-round collaboration of innovative spirit and experience concept. By providing sheet metal processing integrated solutions for overseas customers, Constant Storage Machinery has successfully established an excellent brand perception in the international sheet metal processing field, fully demonstrating the outstanding capabilities of Chinese enterprises in the research and development and application of intelligent manufacturing technology, injecting important strength into the intelligent upgrade of the global manufacturing industry, and also laying a solid foundation for its own sustainable and steady development in the international market.

Latest News