Roll Out Pipe Cantilever Racks

Classification :

Keywords:

Metal Long Material Storage Rack

Product introduction of Roll Out Pipe Cantilever Racks

Roll out cantilever racking is ideal for storing and accessing bar stock, angle iron, tube,pipe, rollers, busbar, mandrels..etc long material and bulk goods, usually work will take a lot of time and find the right items they need if these items are stored on the ground. Roll out racks will increase your work efficiency and save your warehouse space.

Pipe Cantilever Storage Racks

Features of steel pipe storage racks

1.Material is handled by crane, no necessary with wider aisles so save space.

2.Sorting and storing any length of material.

3.Time-saving, material can be operated by crane from rack to terminal directly

4.Solid structure with heavy loading capacity loading Max 5000kgs per layer.

5.100% extended arms, each layers can be accessed easily.

6.Single people can be operated easily.

7.Materials can be stored by categories or size, and tray available for leftovers

8.Single or Double units available (Customized dimension)

9.Electrically Drive roll out racking available.

|

Roll Out Cantilever Rack Parameter |

|||||

|

Item |

Standard |

Customized |

|||

|

Storage Sheet Size |

6000mm |

6000mm |

9000mm |

12000mm |

Customized |

|

Loading Per layer |

2tons |

3tons |

3tons |

3tons |

Customized |

|

Number of layers |

3+1 |

4+1 |

3+1 |

3+1 |

Customized |

|

Single /Double |

Single |

Double |

Double |

Double |

Customized |

|

Total Loading per rack |

8tons |

27tons |

19tons |

21tons |

Customized |

|

Length of Arm |

550mm |

600mm |

800mm |

800mm |

Customized |

|

Distance between two layers |

600mm |

600mm |

800mm |

800mm |

Customized |

|

Operation System |

Mechanical |

Mechanical |

Mechanical |

Mechanical |

Customized |

|

Color of Rack |

Orange/Blue |

Orange/Blue |

Orange/Blue |

Orange/Blue |

Customized |

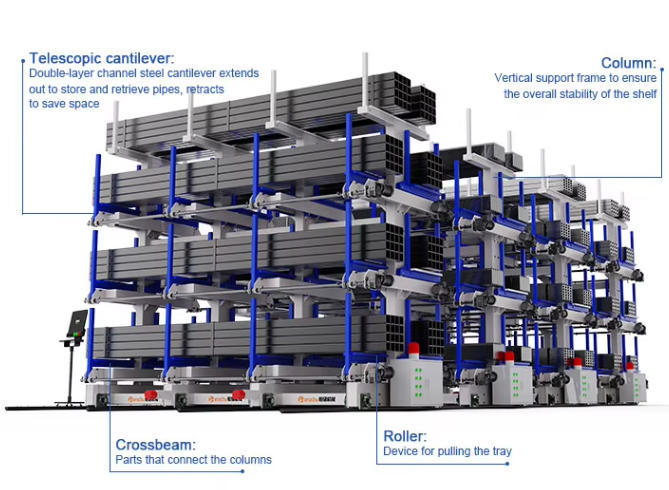

Roll Out Cantilever Racking is an innovative storage solution designed to maximize space efficiency and accessibility in warehouses and industrial settings. This system features a unique roll-out mechanism that allows for easy retrieval of long, bulky, or irregularly shaped items such as pipes, lumber, and steel bars. The cantilever design eliminates the need for front columns, providing unobstructed access to stored materials. With its robust construction and adjustable arms, Roll Out Cantilever Racking offers exceptional durability and flexibility, making it ideal for heavy-duty applications. The roll-out functionality ensures that even the heaviest loads can be smoothly and safely maneuvered, enhancing operational efficiency. Whether you're managing a construction site, manufacturing facility, or retail warehouse, Roll Out Cantilever Racking is the ultimate solution for optimizing storage space and improving workflow. Its user-friendly design and superior load-bearing capacity make it a must-have for any business looking to streamline its storage processes.

In modern manufacturing, construction, and logistics industries, efficient storage and easy access to heavy, long materials like pipes, bars, and tubing are crucial for productivity and safety. Roll Out Pipe Cantilever Racks have become the preferred solution for companies seeking to optimize their material handling operations without sacrificing valuable floor space or worker safety.

1. Product Overview

The Roll Out Pipe Cantilever Rack System is an advanced material storage design that allows each arm level to smoothly roll out, giving operators direct access to stored pipes or bars without lifting or excessive manual handling. Built with a heavy-duty steel framework, precision bearings, and a roll-out mechanism, it enables quick retrieval of materials while maintaining a clean, organized workspace.

Each cantilever arm can be independently extended and locked in position, providing full visibility and safe handling during loading and unloading. The system is available in manual or electric-powered configurations to suit various industrial environments, from small workshops to large-scale metal fabrication plants.

2. Advantages and Technical Features

a. Space Optimization

Traditional static racks require large aisle space for forklifts or cranes. Roll Out Pipe Cantilever Racks, however, maximize vertical and horizontal space, allowing denser storage and better utilization of workshop areas.

b. Easy and Safe Operation

The roll-out mechanism ensures smooth movement of each arm, minimizing lifting hazards and improving worker safety. With hydraulic or mechanical assistance, operators can access even the heaviest pipes effortlessly.

c. Heavy-Duty Load Capacity

Designed with industrial-strength steel, the system supports extremely high loads. Reinforced arms and stable bases prevent deflection or bending, ensuring long-term structural integrity.

d. Customizable Design

Each rack can be customized for length, height, and load capacity, tailored to specific material sizes and warehouse layouts. Optional safety stops, arm locks, and rollers can be added for specialized needs.

e. Durable and Low Maintenance

Powder-coated finishes provide corrosion resistance and a long service life, even in humid or outdoor environments. The simple mechanical structure ensures minimal maintenance and easy repair when needed.

3. Application Scenarios

-

Steel and Metal Processing Plants: Efficient storage for pipes, bars, and metal rods used in machining and fabrication.

-

Construction Material Warehouses: Ideal for long construction materials such as conduits, rebar, and scaffolding.

-

Machinery Manufacturing: Streamlines the storage and retrieval of shafts, rollers, and tubes.

-

Automotive and Aerospace Facilities: Ensures safe organization of precision metal components and tubes.

4. Case Example

A leading metal fabrication company in Southeast Asia replaced its traditional shelving with 12 sets of roll-out cantilever racks. The result was a 40% increase in storage capacity and a 35% reduction in material retrieval time. Workers reported fewer handling injuries, and the company improved operational flow dramatically.

5. Solving Customer Pain Points

Before adopting Roll Out Pipe Cantilever Racks, many businesses face common issues:

-

Wasted floor space due to inefficient static storage systems

-

Safety hazards from manual lifting of heavy pipes

-

Time-consuming material retrieval processes

-

Frequent damage to stored materials due to improper stacking

This innovative racking system solves all these challenges through ergonomic design, modular flexibility, and superior safety features.

6. Conclusion

The Roll Out Pipe Cantilever Rack is more than just a storage solution—it’s a productivity enhancer. It allows industries to manage heavy materials efficiently while maintaining the highest standards of safety and organization. Whether in steel processing, construction, or manufacturing, this system empowers businesses to operate smarter, safer, and more efficiently.

Customer visit

Constantstorage has always been adhering to the market-centric approach to meet customer requirements to the maximum extent, and the business philosophy of "creating brands with heart and gaining reputation with sincerity". It provides customers with high-quality products and services with rigorous military quality, professionalism, and excellence, and has won unanimous praise in the Chinese aerospace, Chinese weapons, Chinese railways, automobile manufacturing, engineering machinery, non-ferrous metal titanium alloy and other industries.

RELATED PRODUCTS

GET A FREE QUOTE