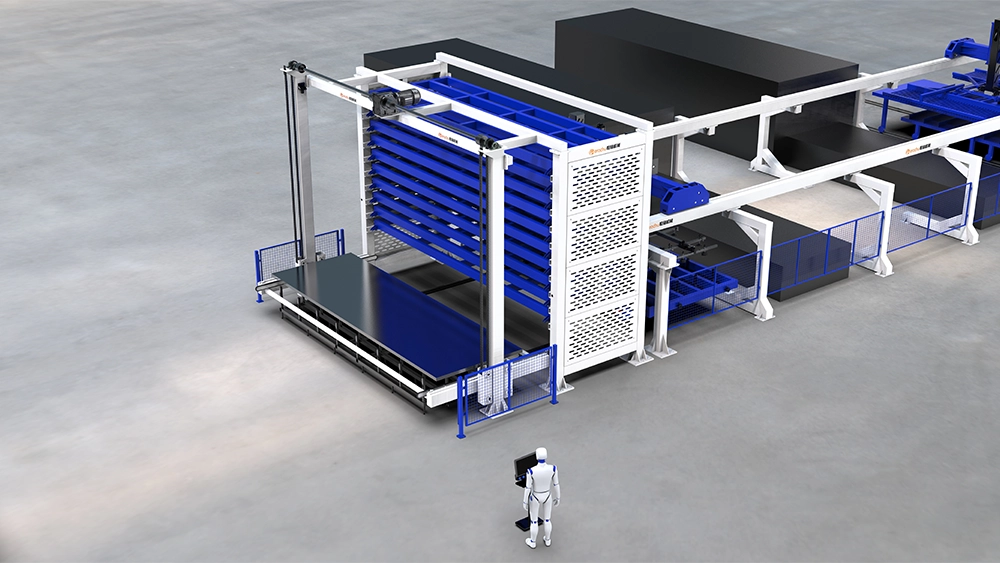

Single gantry composite loading and unloading + sheet metal storage warehouse

Classification :

Keywords:

Automation sheet metal cutting and storage

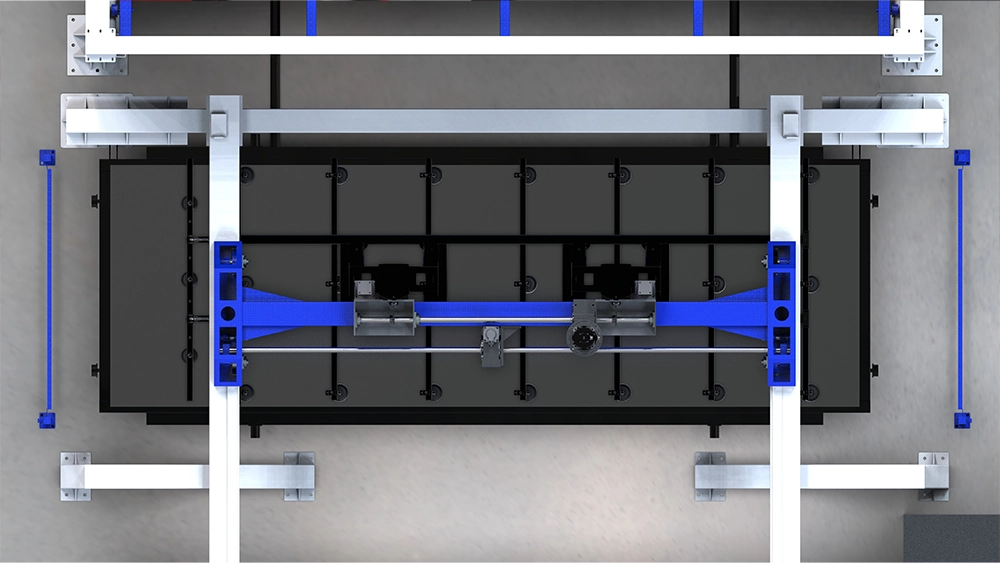

This system consists of a three-dimensional storage material warehouse, a double-sided gantry truss,a suction cup type loading manipulator,

a fork type unloading manipulator, a double-layer electric exchange material car, a CNC control system, a vacuum control system, etc.

Specification | 3015/4015/4020mm |

Number of floors | 8-13 |

Load per layer | 3T |

Maximum load | 100KG-500KG |

Skip load | 3T |

Air consumption | 1.5m³/min |

Sheet metal storage systems are specifically engineered to optimize space, improve material organization, and enhance workflow in industrial environments. These systems offer a practical and efficient way to store large volumes of sheet metal while minimizing damage and maximizing accessibility. With sturdy construction and smart design, sheet metal storage systems ensure that materials are kept secure, well-organized, and ready for immediate use.

Designed to handle various sheet sizes and weights, sheet metal storage systems are ideal for factories, fabrication shops, and warehouses dealing with metalworking operations. These systems reduce clutter and downtime by enabling fast retrieval and restocking, contributing to a safer and more productive work environment. Whether storing aluminum, stainless steel, or carbon sheet metals, the storage solution maintains the quality and integrity of each piece.

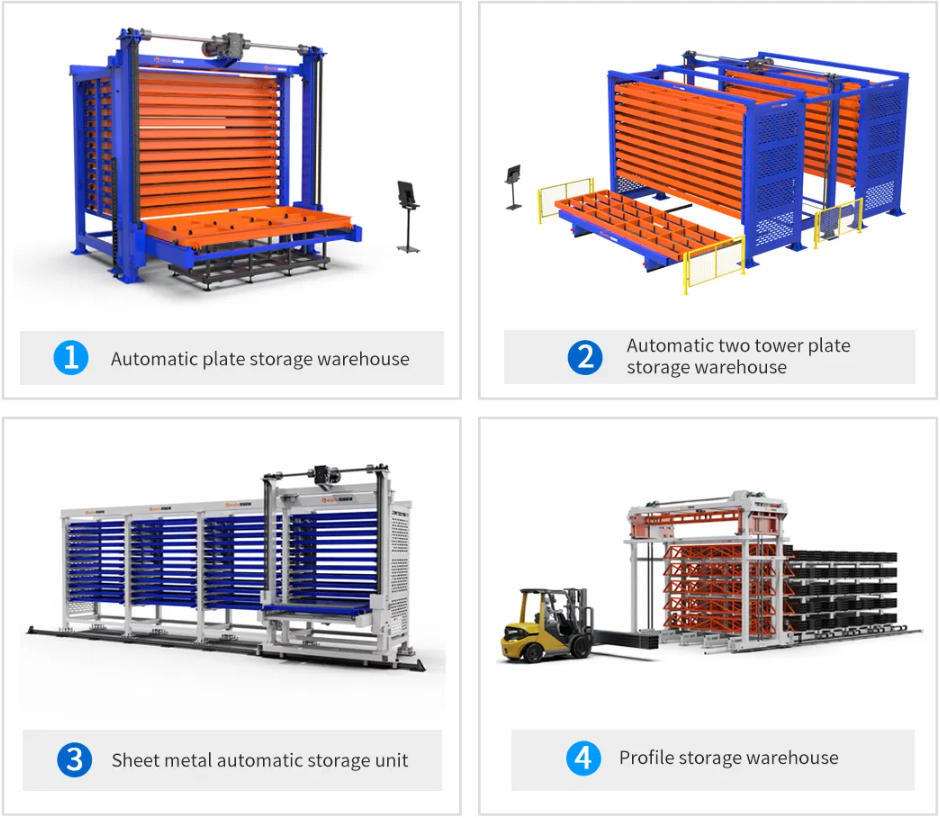

A major advantage of sheet metal storage systems lies in their modularity and adaptability. They can be customized to meet specific floor plans and workflow needs, offering configurations such as roll-out shelves, vertical racks, or automated towers. The versatility of these systems supports both manual and automated handling equipment, ensuring they integrate seamlessly into existing material handling operations.

Durable finishes and high-load capacities make sheet metal storage systems a long-term investment. Their space-saving design not only increases storage density but also enhances operational efficiency by reducing the time spent locating and moving materials. Facilities that implement these systems often see immediate benefits in inventory control, safety, and overall throughput.

Customer visit

Constantstorage has always been adhering to the market-centric approach to meet customer requirements to the maximum extent, and the business philosophy of "creating brands with heart and gaining reputation with sincerity". It provides customers with high-quality products and services with rigorous military quality, professionalism, and excellence, and has won unanimous praise in the Chinese aerospace, Chinese weapons, Chinese railways, automobile manufacturing, engineering machinery, non-ferrous metal titanium alloy and other industries.

RELATED PRODUCTS

GET A FREE QUOTE